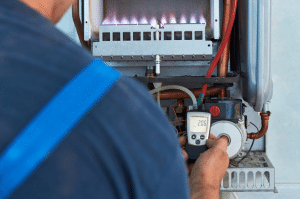

Engine Starter Maintenance

Customarily, engine starters require no upkeep other than surprisingly covering the development, since development might cause irrational warming and contact wear. Never record the contacts. Recording gets rid of the silver covering of the spots, which can incite helpful issues by Boiler Repairs Coventry .

Programming Control Maintenance

The programming control needs no assistance other than to win any aggregated development. Never record any contacts. Assuming the contacts look messy or impalpably oxidized, clean them by drawing a piece of hard-completed paper between the contacts. Reliably keep the scanner point of combination clean—even a limited measure of tainting will diminish the fire sign to the lead-sulfide photocell. Clear the mark of combination off with a delicate surface. Exactly when worked inside sensible temperature restricts, the cell has a typical presentation of 20,000 hours.

Since high dampness can cause high hindrance spillage in the electric circuit, it is ideal to leave power on the control in any case, when the evaporator isn’t being used. Regardless, make a point to disappoint the fuel supply to stay away from unintentional startup. Test the fire disappointment contraption and programming control dependably to guarantee they are working fittingly.

- Changing Pressure Control Maintenance: Other than extinguishing the development with compacted air at standard ranges, no field support is suggested on the coordinating pressure control.

- Changing Motor Maintenance: A changing engine is a legitimate unit; don’t give support a shot to it. Assuming the unit fizzles, supplant it with an equivalent, working unit.

- Oil Solenoid Valve Maintenance: The oil solenoid valve ought to be seldom destroyed and cleaned. Hold quick to the maker’s principles for cleaning.

- Gas Solenoid Valves Maintenance: Gas solenoid valves reliably shouldn’t worry about help. Tolerating a valve becomes out for the count, the clarification is no doubt a defective or obliterated circle that should be supplanted.

- Electrical Wiring Maintenance: Electrical wiring on boilers can fall to pieces from high temperatures and vibration. Right when it becomes crucial to supplant a piece of the wiring, utilize an affirmed circuit analyzer. Electrical wiring on boilers should change with the principles spread out in electrical codes.

- Various Equipment in Oil-Fired Burners: The metering, or control, the valve shouldn’t worry about any standard assistance. Notwithstanding, expecting the valve becomes stopped up, it should be obliterated and cleaned.

For boilers outfitted with air atomizing oil burners:

Oil shower air channel (vacuum contraption certification): Service this unit consistently as shown by the heading given on the air channel. Replace the oil at standard ranges and remain mindful of it at the showed level.

- Pneumatic machine: No assistance is proposed. Expecting the unit becomes done for, return it to the cutting edge office or shipper for fix or substitution.

- Pneumatic machine oil channel gathering (vacuum contraption release): The sifter in the lube oil channel ought to be taken out and cleaned one time every month.

- Oil more blazing: The steam or electric warming pieces of radiators utilized for significant fuel oils ought to be cleaned yearly. In the event that the radiator acts sluggish, it should be cleaned much more regularly. Any aggregation of carbonized oil or another improvement ought to be taken out.